Make Enquiry

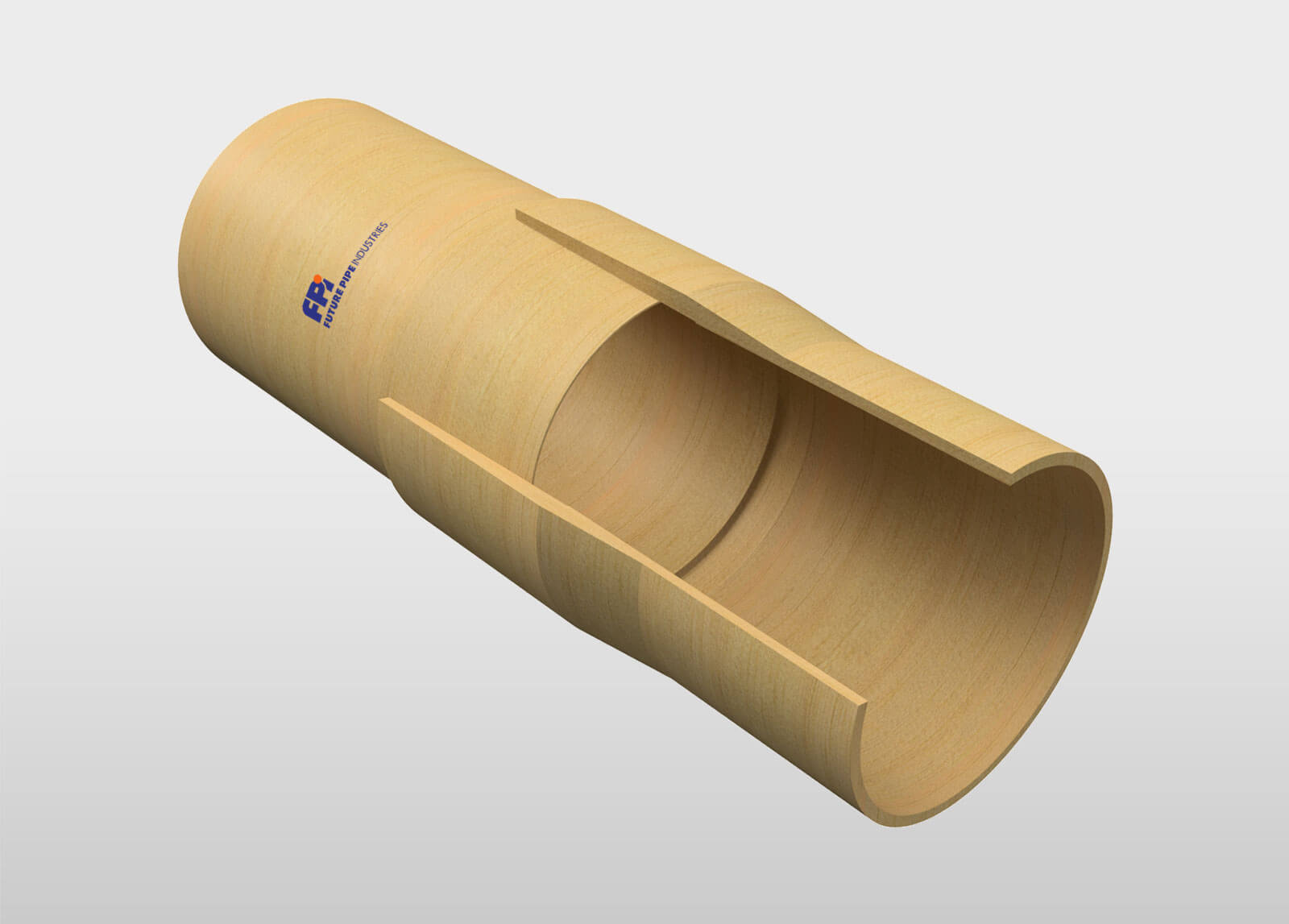

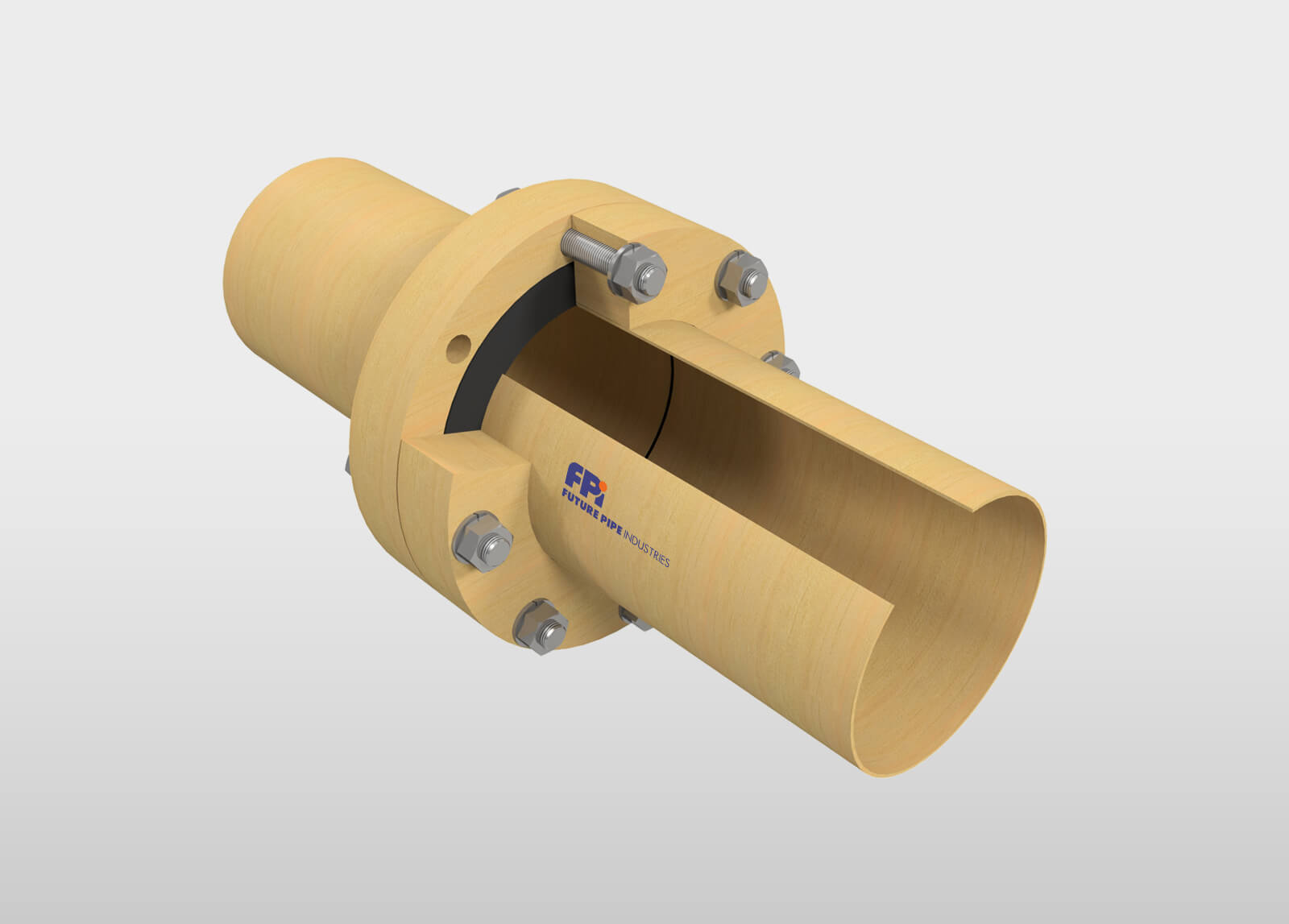

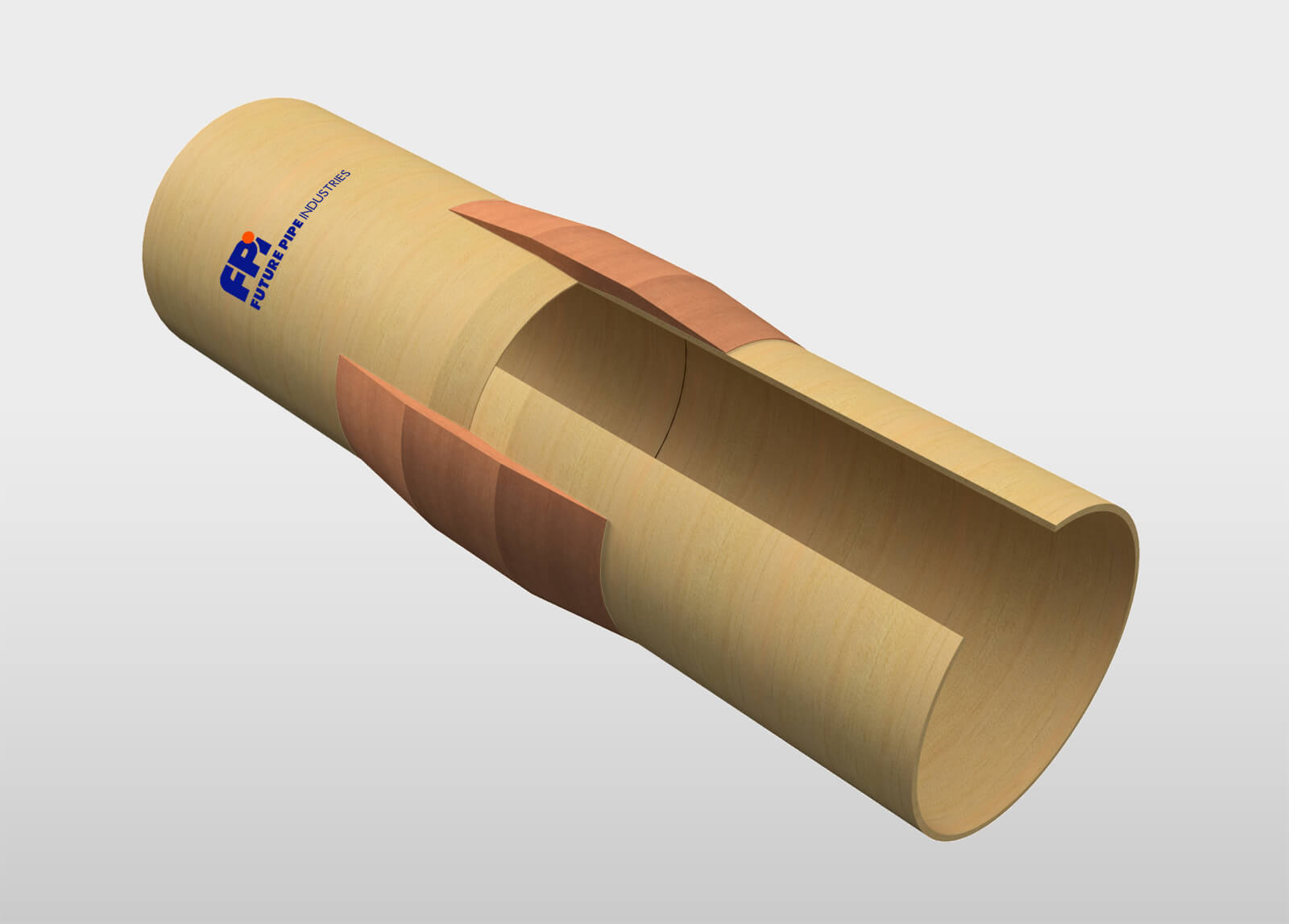

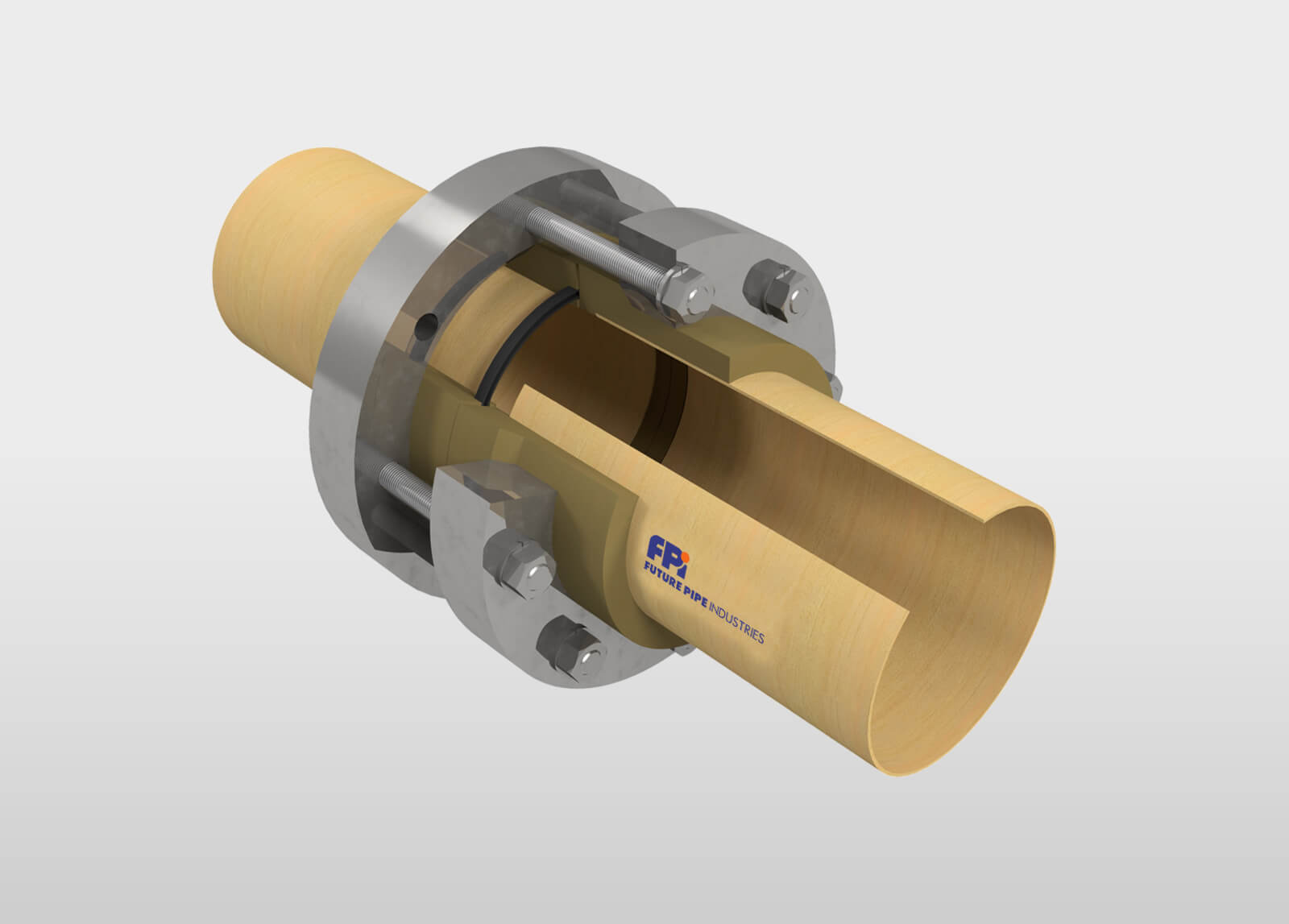

GRE

WAVISTRONG® GREEN (UPW) Series

Hydrogen produced through the electrolysis typically referred to as a Green Hydrogen, is produced by the electrolysation of ultra-pure demineralised water. The Alkaline production process utilises the addition of potassium hydroxide to form an electrolyte, however the Proton Exchange Membrane process (PEM) splits the demineralised water directly.

While the internal pipework of the individual cells is typically small in diameter, when combining multiple cells on a large-scale PEM electrolyser, the volume of water requirements can increase significantly. Increased demand leads to increased pipework diameters.

Dealing with ultra-pure demineralised water is particularly challenging due to the interaction between the demineralised water and the metal pipes, as demineralised water dissolves metal ions from the steel due to its high balancing potential and thus contaminates the water.

Ensuring that the water is ultra-pure and free of impurities is crucial for the long-lasting operation of a PEM electrolyser. The combination of the in-house manufacturing process and independent suitability testing ensures that WAVISTRONG® GREEN (UPW) series is free from contamination and suitable for safe and sustainable use in the electrolysis process. Therefore, WAVISTRONG® GREEN (UPW) series offers an extremely cost-effective, low carbon solution for Ultra-Pure Water service.

Product Range

WAVISTRONG® GREEN (UPW) series pipes and fittings range from 1” (DN 25 mm) to 48” (DN 1200 mm) in diameter and can withstand pressures up to 63 Barg (914 Psig) and temperature range from -60oC (-76oF) up to 121oC (212oF).

WAVISTRONG® GREEN (UPW) series can be supplied as conductive, and externally coated with Polyurea (PU) impact-resistant coating for aboveground installation where required.

Applications

WAVISTRONG® GREEN (UPW) series is the ideal pipe system for Demineralized Ultra-Pure Water for Green H2 production Electrolysis.

Downloads

01/ 03

Downloads

WAVISTRONG Energy Transition Brochure (English)

Need More

Information?

Let us know how can we assist you.

Contact us