Make Enquiry

Energies

Oil & Gas

As the world energy demand continues to rise, the Oil & Gas industry is increasing its exploration and production activities and will continue to play an important role in the energy transition by providing affordable and reliable energy.

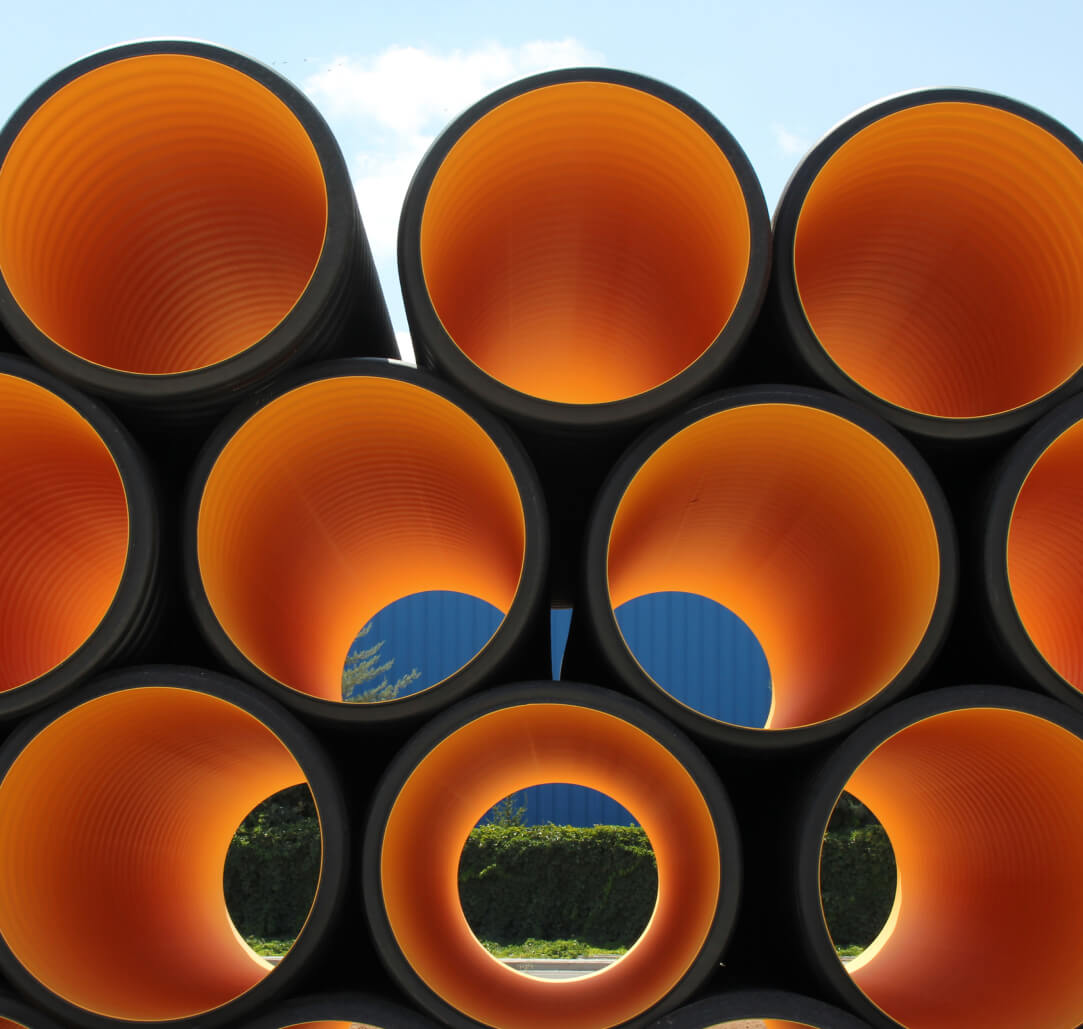

The non-corrosive characteristics of composite material piping systems position them as the materials of choice for efficient transportation on the full value chain of the upstream Oil & Gas industry, from the hydrocarbon reservoirs to the processing units.

Our Expertise

01

Wells equipment - Casing and Tubing

FPI provides downhole solutions to equip all kinds of wells for water, oil and gas, geothermal and carbon storage applications. The use of non-metallic composite pipe downhole allows the operators to significantly reduce the weight of their wells while offering superior resistance against corrosive environment. By eliminating the needs for complex and costly maintenance operations, the lifetime of the wells is increased. Thanks to its very smooth interior surface compared with traditional material, the non-metallic pipes also improve the flow rate of production further reducing the operational costs.

Well equipment - Cement Stingers

FPI provides non-metallic composite cement stingers which are used in the oil and gas well construction for various applications such as well plug & abandonment (P&A), open hole side-tracking, and curing mud losses. The use of FPI sacrificial pipes both eliminates costly risks associated with steel pipes for those operations (pipe stuck in hole), and allows the use of fast drying cement to cure losses in the most efficient way.

Well equipment - Tubes for Coring

FPI provides non-metallic composite pipes used for soil coring in mineral and Oil & Gas explorations. The inner wall of the pipes is extremely smooth providing low friction suitable for all coring applications primarily from soft or fractured formations to hard and abrasive formations.

Transmission Line – GRE Line pipes

FPI has vast experience in designing and supplying transmission lines for hydrocarbons, chemicals, and water connecting gathering centres, Gas Oil Separation Plants, distribution centres, and storage facilities.

The benefits of using Glass Reinforced Epoxy (GRE) material, also called Reinforced Thermosetting Resin (RTR), for transportation of fluids in the Energy sector include, but not limited, to:

- Elimination of corrosion due to the anti-corrosive behaviour of this material.

- Extending the lifetime of the pipeline to a minimum of 20 years.

- Low friction losses over the entire lifetime of typical oil & gas services

- Cost effective compared to protected steel alternatives, so reducing CAPEX.

- Minimal maintenance enabling lower OPEX costs.

- Products complying with ISO 14692 and API 15HR, an internationally recognised oil & gas standards.

Transmission Line – High Pressure Spoolable pipe

FPI developed a fully bonded Thermoplastic Composite Pipe (TCP), suitable for use across a broad range of applications in the Oil & Gas and Water industries, including environmentally sensitive areas and replacement to failed steel pipelines. It is commonly used as transmission lines for produced fluids, water injection, brine and natural gas.

The use of spoolable pipes offer several benefits versus traditional solutions:

- high pressure capacity

- corrosion free,

- length up to 1,100 m (3,610 ft)

- rapid installation

- flexible,

- exceptional durability,

- lightweight transportability

Relevant Products

Get in Touch

Id magna nunc sed nulla convallis sagittis tristique tempus. Eget faucibus tellus urna.