Make Enquiry

GRE

FLOWSTRONG® YELLOWBOX® and GREENBOX®

FLOWSTRONG® line pipes and fittings are designed by Future Pipe Industries for medium to high pressure oilfield and industrial services where operating conditions include exposure to corrosive or otherwise chemically aggressive fluids or gases.

Produced by winding high-strength continuous glass fibers and corrosion resistant epoxy resin on to a steel mandrel, the material is formulated to result in a product which is structurally and chemically optimized.

The resin system used is an epoxy thermoset resin, heat cured with an aromatic amine-based hardener. This formulation results in the strongest, most thermal resistant and anticorrosive of all commercially available resin systems used in the production of fiberglass piping.

Both FLOWSTRONG® YELLOWBOX® and FLOWSTRONG® GREENBOX® product lines are available for size range 2″ to 16” in diameter, and designed to withstand pressures up to 207 Barg (3,000 PSI) and temperatures up to 100oC (212oF).

Applications

Building upon the unparalleled mechanical performance that FLOWSTRONG® YELLOWBOX® and FLOWSTRONG® GREENBOX® product lines deliver, the FLOWSTRONG® GREENBOX® are made with an additional inner resin rich liner for an enhanced chemical resistance in highly corrosive environments where required.

FLOWSTRONG® is used primarily for line pipes, including but not limited to:

– Power Injection Lines

– Water Flood Lines

– Transmission and Trunk Lines

– CO2 Injection & Recovery Lines

– Sweet and Sour Hydrocarbon Liquid and Multiphase Flowlines

– Sweet and Sour Dry and Wet Gas Flowlines

– Condensate Lines

– Produced Water Transmission Lines

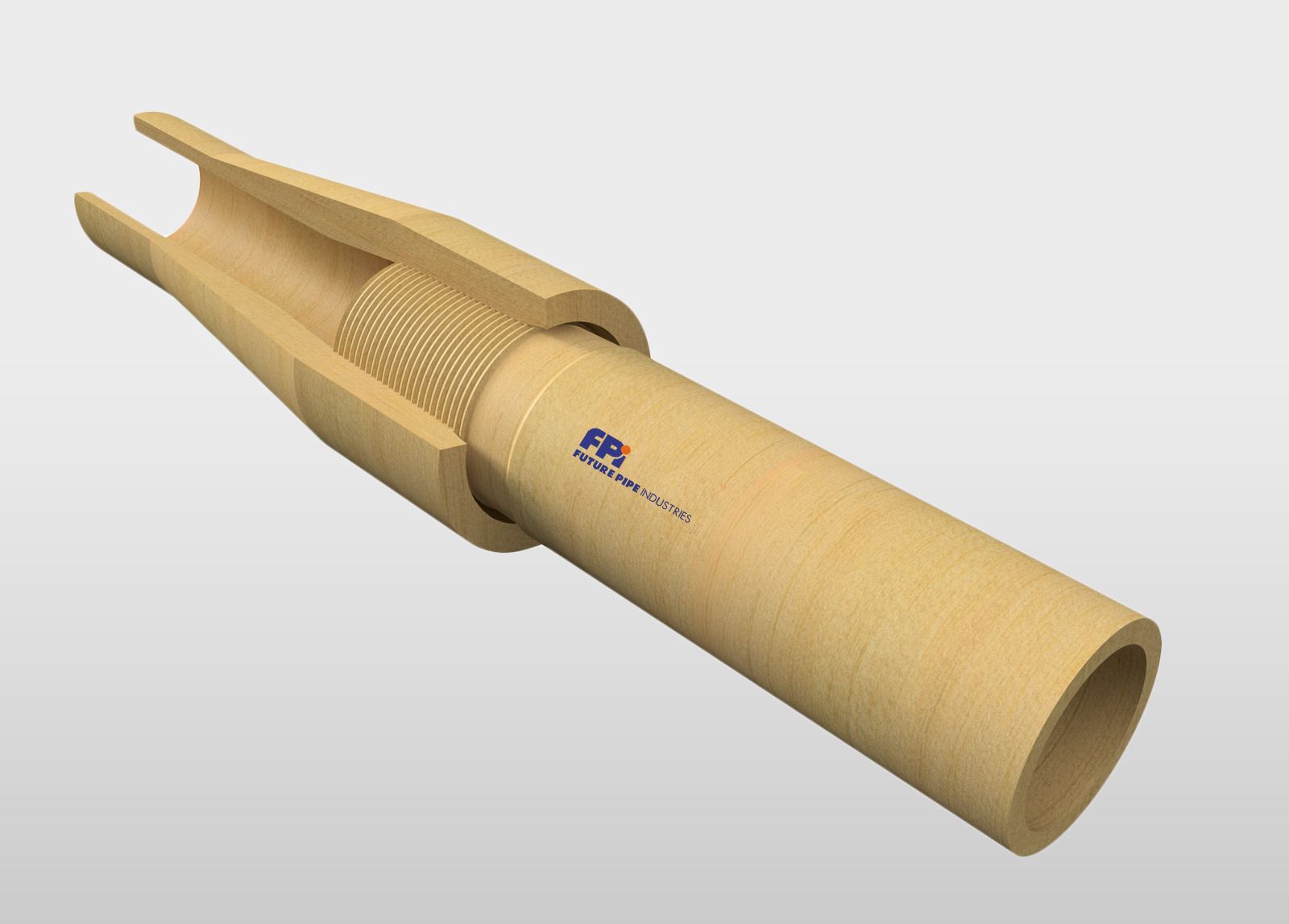

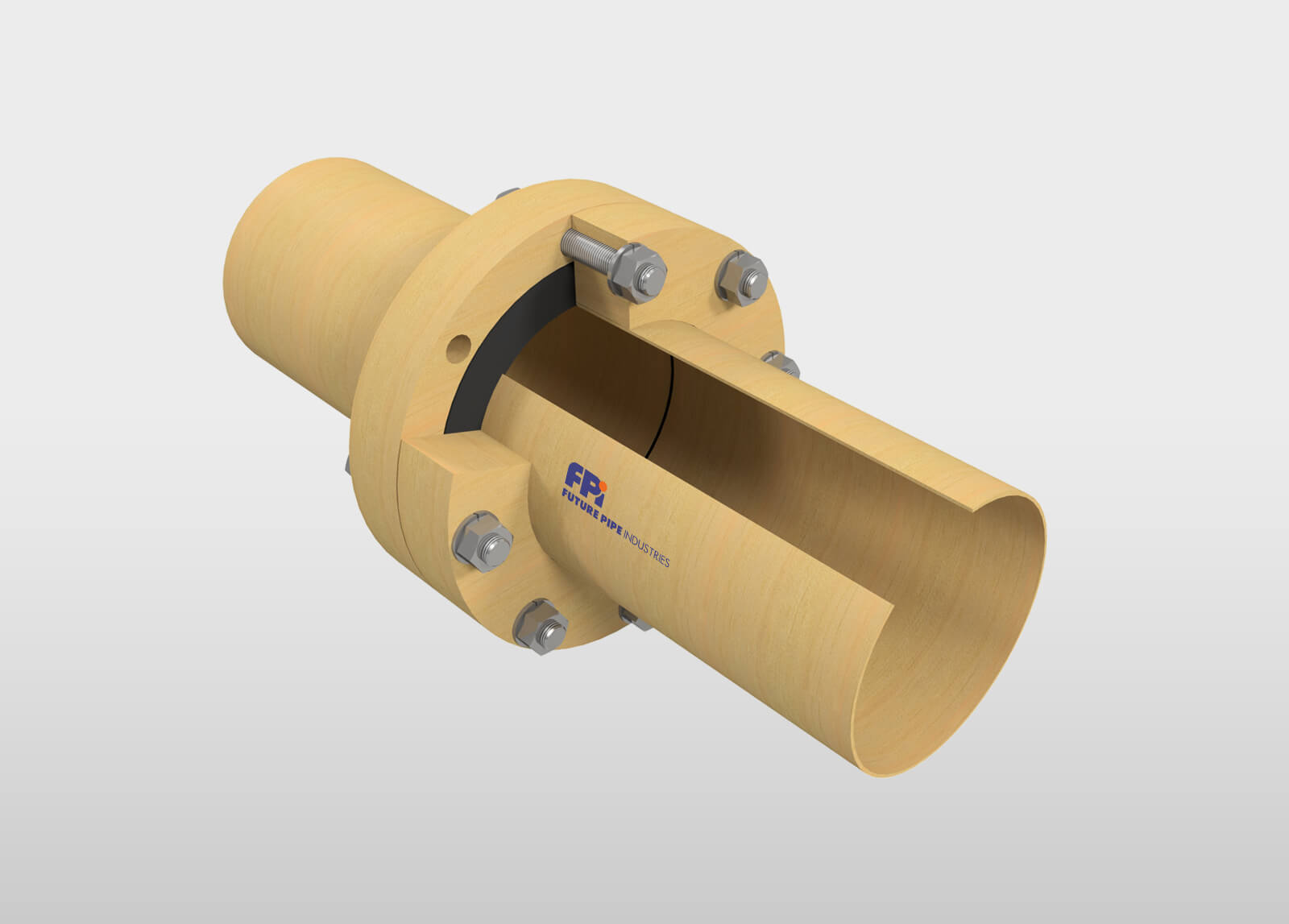

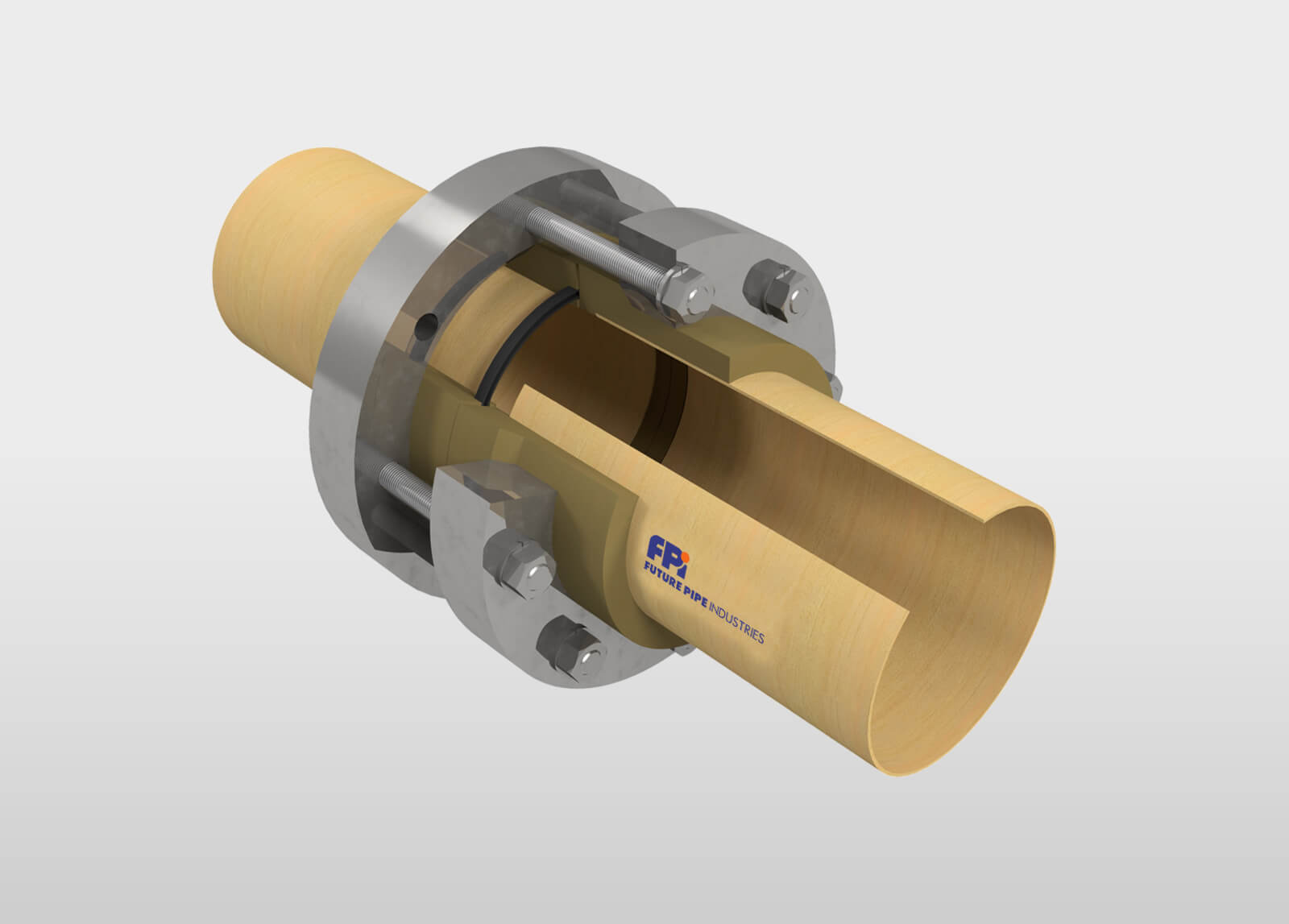

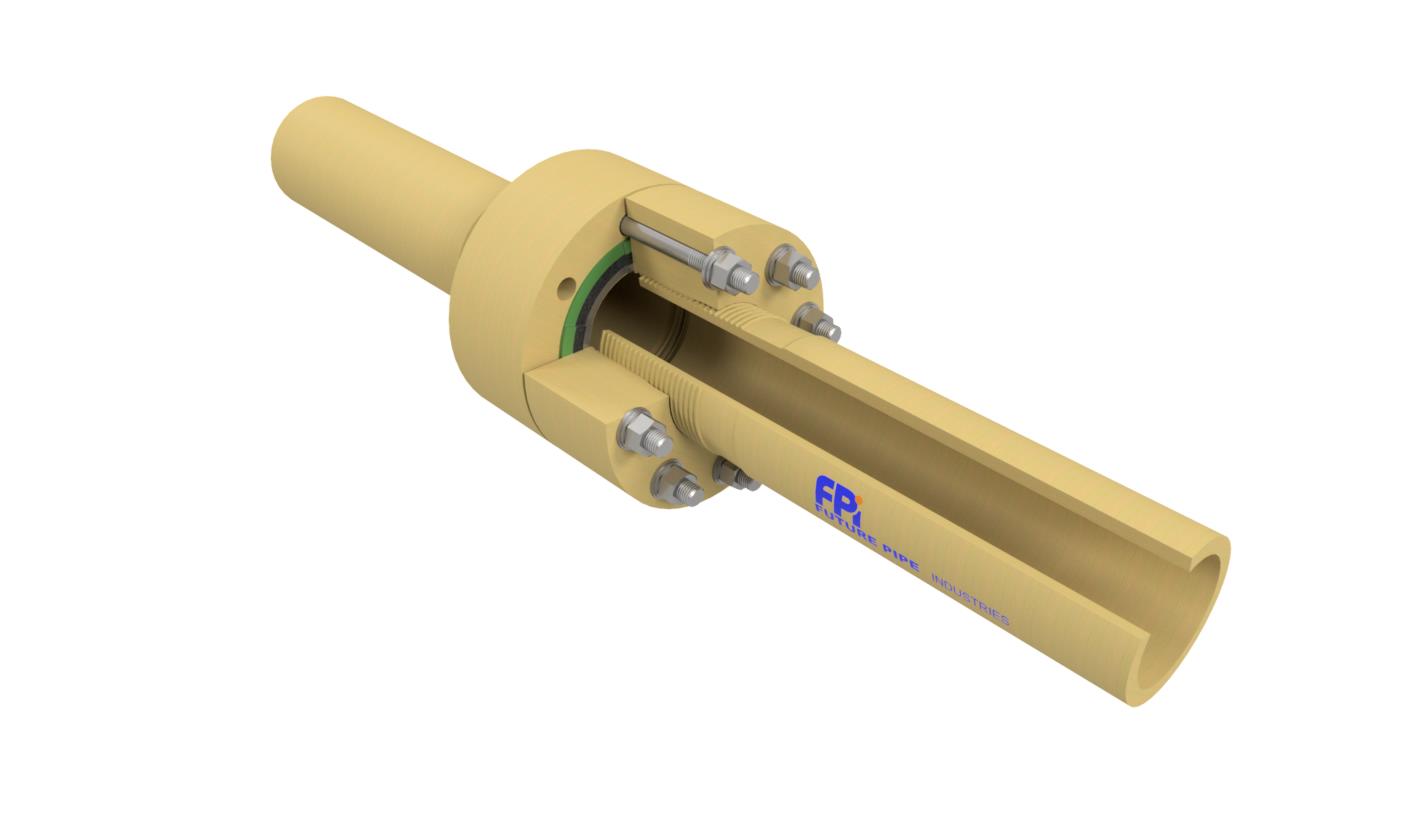

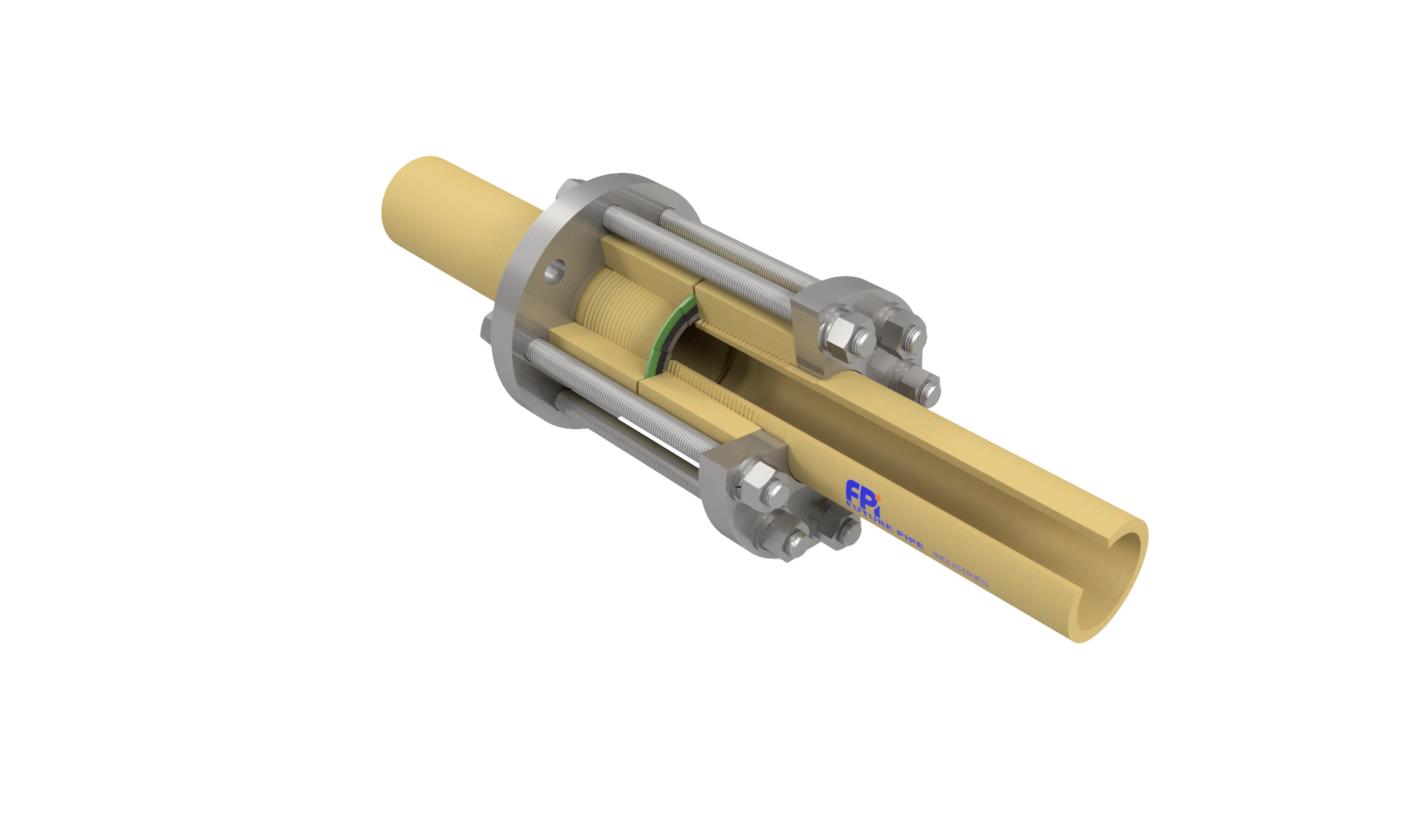

Jointing Systems

01/ 03

Available Sectors

Downloads

FLOWSTRONG Flyer

Need More

Information?

Let us know how can we assist you.

Contact us