Make Enquiry

GRE

WAVISTRONG® GREEN (H2) Series

WAVISTRONG® GREEN (H2) series GRE – the world’s first qualified composite material for hydrogen transport.

FPI WAVISTRONG® GREEN (H2) series GRE has been officially certified for transporting 100% hydrogen under real operating conditions. Our solution has been independently verified by TÜV SÜD.

WAVISTRONG® GREEN (H2) series GRE is a development of Future Pipe Industries highly successful Wavistrong Oil & Gas product range tailored to meet the needs of the hydrogen industry. Key challenges for Hydrogen and Ammonia service are mechanical integrity and permeation management. As hydrogen specific standards for non-metallics are still evolving Future Pipe Industries design philosophy for mechanical integrity is based on ISO 14692 (2017) which is widely accepted within the Energy industry as the most arduous non-metallic standard available. Permeation control has been developed through third party independent testing resulting in a design and manufacturing process that provides a permeation level many times lower than the equivalent steel component. WAVISTRONG® GREEN (H2) series can also be supplied with an external Polyurea (PU) impact resistant coating for above ground service where required and pre-insulated for Ammonia service.

To capitalize on the potential of Hydrogen, the industry must find ways to transport it safely and efficiently over long distances at scale cost effectively and environmentally sustainably compared to other forms of renewable energy. With the further development of Green Ammonia for global shipping of hydrogen dense liquids pipelines play a pivotal role in the Hydrogen Economy.

Hydrogen presents a unique challenge for steel, due to hydrogen embrittlement, low molecular weight, and low calorific value. The drive is to repurpose existing gas networks and while usable life can be extended through internal coatings, hydrogen will permeate barrier layers ultimately affecting the steel carrier pipe. New installations can be built using hydrogen resistant steels however these alternatives come at an environmental and material cost. Therefore, steel while being technically capable does not resolve the long term 100% Hydrogen solution. Thermoset GRE composites which are universally accepted in aerospace do however provide a long-term solution.

Product Range

WAVISTRONG® GREEN Hydrogen (H2) series pipes and fittings range from 1” (DN 25 mm) to 48” (DN 1200 mm) in diameter, and designed to withstand pressures up to 50 Barg (725 Psig) and temperature range from -60oC (-76oF) up to 121oC (212oF).

WAVISTRONG® GREEN Hydrogen (H2) series can be supplied as conductive, externally coated with Polyurea (PU) impact-resistant coating for aboveground installation where required, as well as pre-insulated for Ammonia services where deemed necessary.

Applications

WAVISTRONG® GREEN Hydrogen (H2) series is the ideal pipe system for Hydrogen Production, Storage, Transmission and Blending.

Composite Piping Capabilities

Key Features

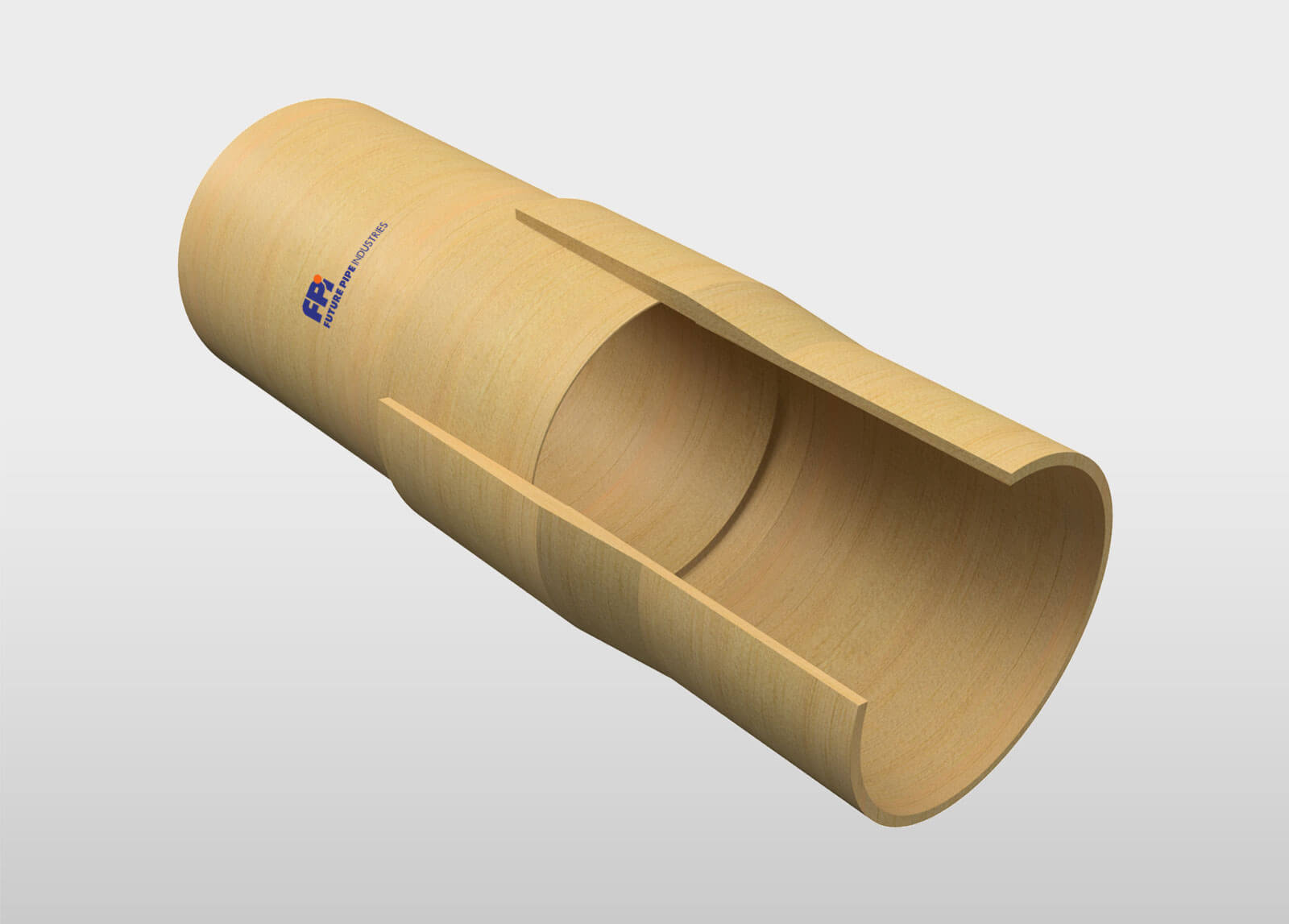

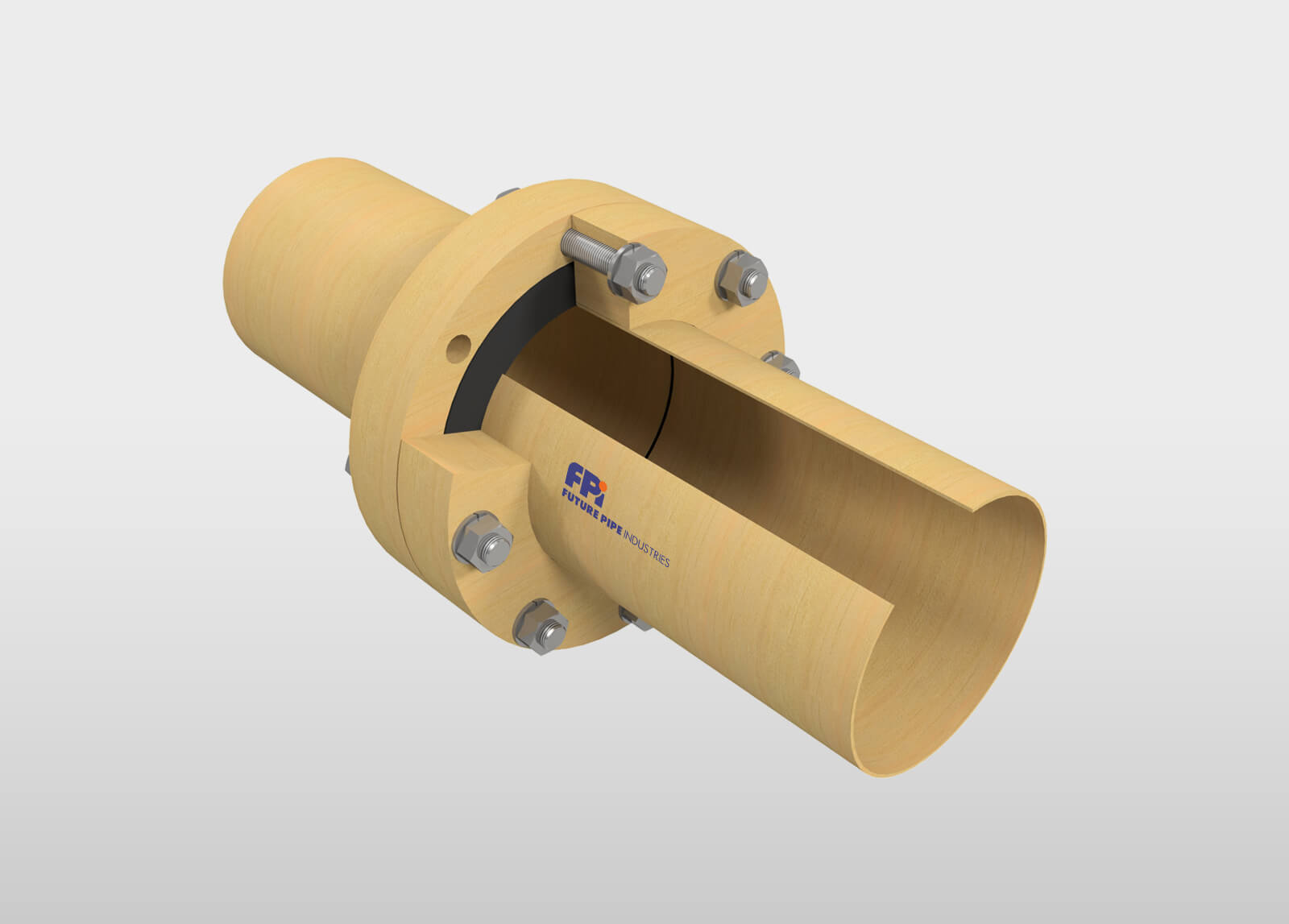

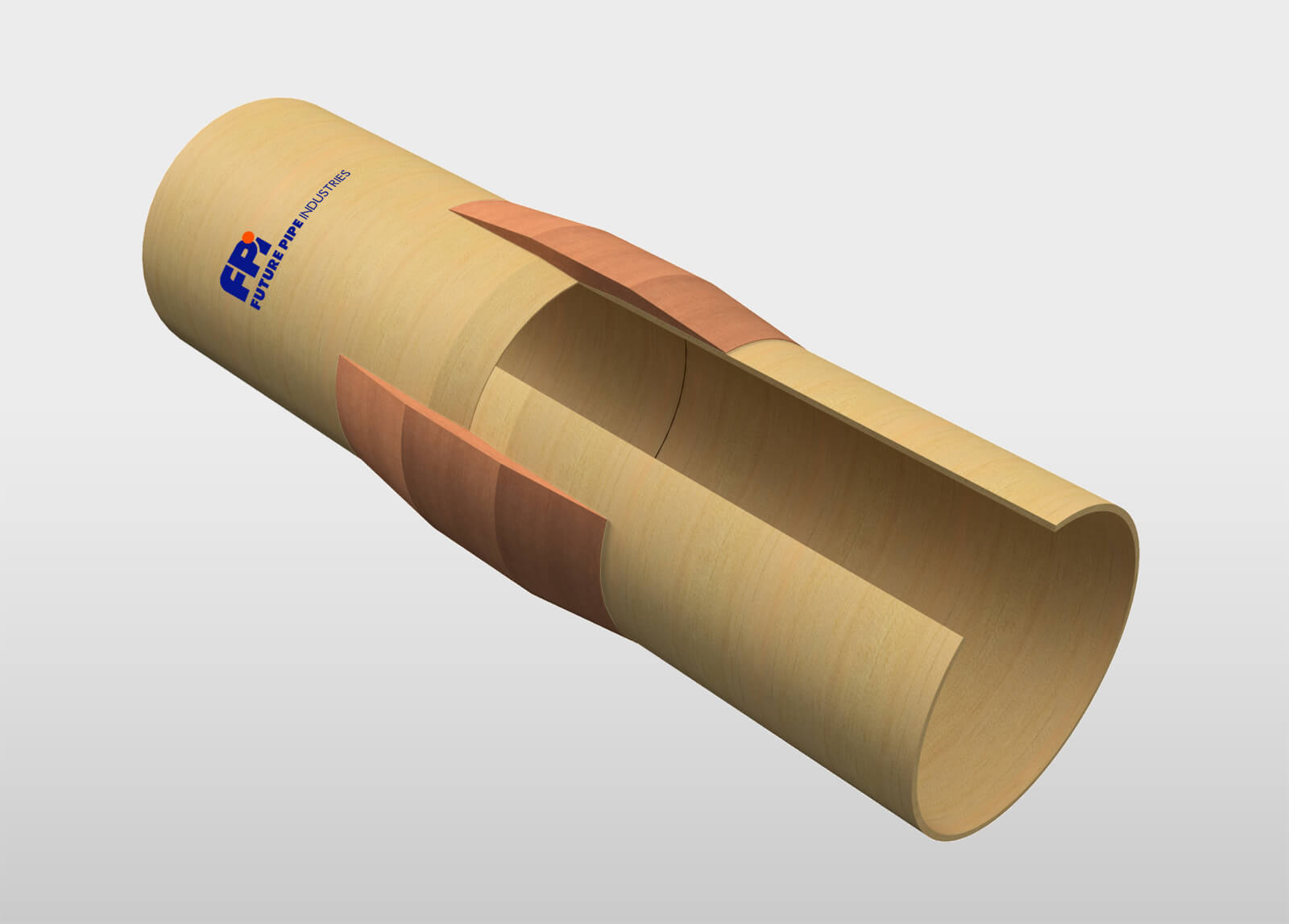

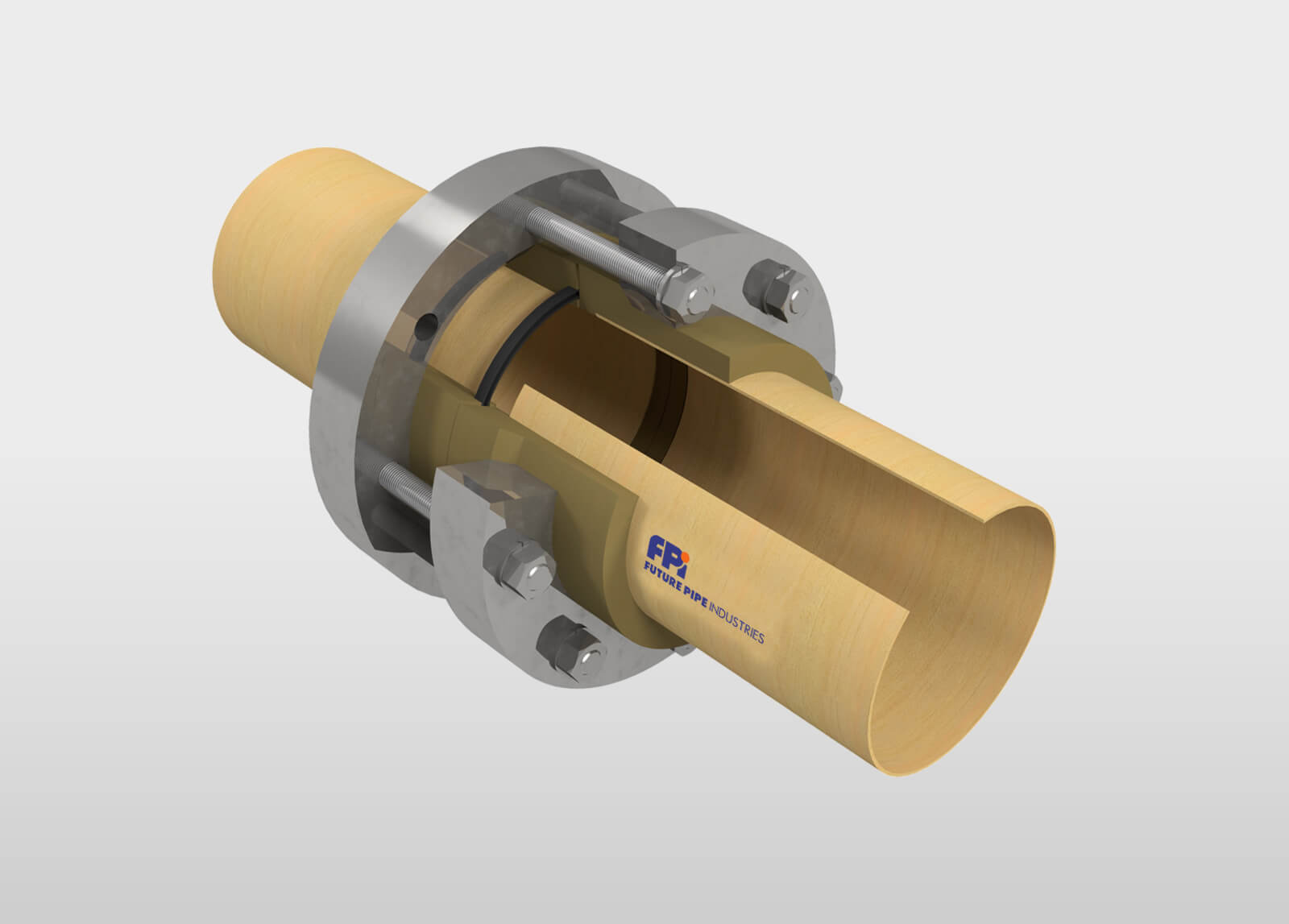

Jointing System

01/ 03

Downloads

WAVISTRONG Energy Transition Brochure (English)

Need More

Information?

Let us know how can we assist you.

Contact us